Bespoke solids management systems to address your unique well challenge

Delivering a range of functional requirements, this range of axillary equipment can be utilised alongside our separation units to create bespoke solids management systems.

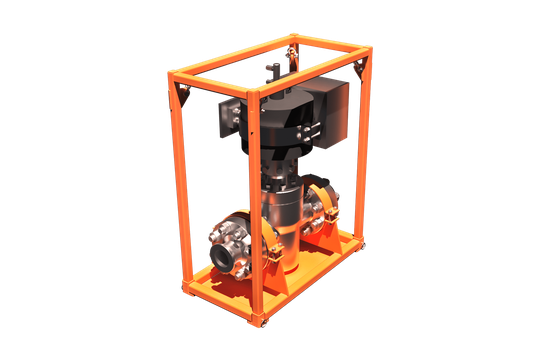

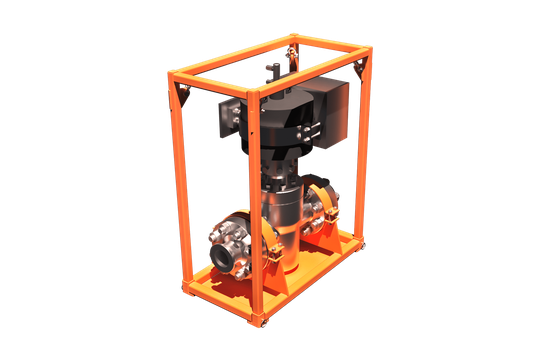

5K Surface Safety Valve (SSV)

Developed for contingency in any flowback operation to shut-in the well stream quickly and effectively. The Surface Safety Valve is controlled by either the Emergency Shut Down (ESD) system or local trigger points. This means that the unit is fail safe. It can be used with any FourPhase separation unit or as a standalone application.

The SSV is also available in 10K and 15K pressure ratings.

The SSV is also available in 10K and 15K pressure ratings.

Technical Specification 5K SSV

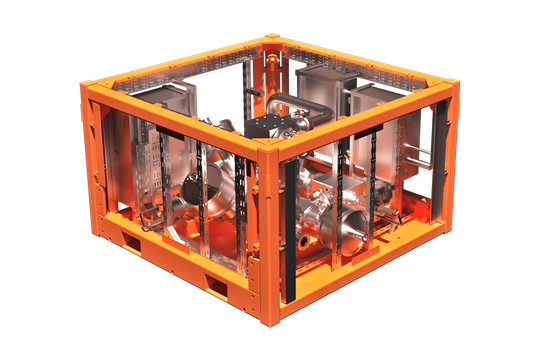

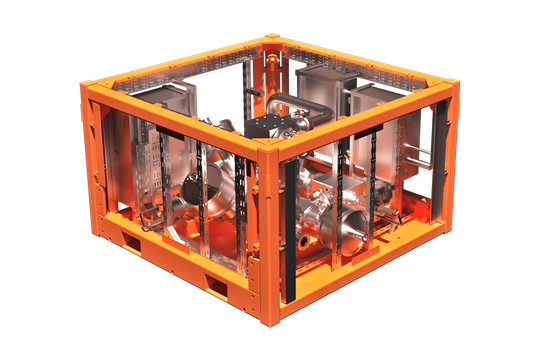

Choke Manifold

Consisting of two individual choke valves within an integrated changeable flow path, the 5K Choke Manifold is designed for various offshore situations. These include offshore production rigs, maintaining pressure control upstream or downstream off the solids removal system.

Technical Specification 5K Choke Manifold

X-Flow Choke

Designed to withstand the extreme erosional forces that occur in a sandy environment, the X-Flow Choke consists of two individual choke valves with integrated changeable flow path. The arrangement of valves (X-Flow) allows for multiple wellbores and separators to be connected without the need for physical re-arrangement of pipework. It is used to control a liquid or gas medium and typically reduces the amount of temporary flowback iron commonly in half.

Technical Specification 5K X-Flow Choke Manifold

MPFM (Multi-Phase Flow Meter)

The multiphase flowmeter together with the FourPhase DualFlow desander system provides valuable insight about well productivity through accurate measurement of the 4 phases without the need for a dedicated production or test separator.

Technical Specification MPFM

Filter Unit

Intended for use in offshore topside applications where solids could be present at surface from wellbore flow back. The Filter Unit efficiently removes solids upstream of the production system.

Technical Specification Filter Unit

Solids Cleaning System

Using a fluidised bed to actively separate oil from solids, it enables clean sand to be disposed to sea. The Solids Cleaning System guarantees sand cleaning to below 1% weight hydrocarbons on oil contaminated solids.

Technical Specification Solids Cleaning System

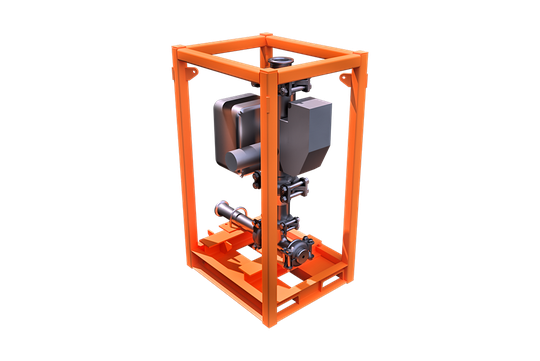

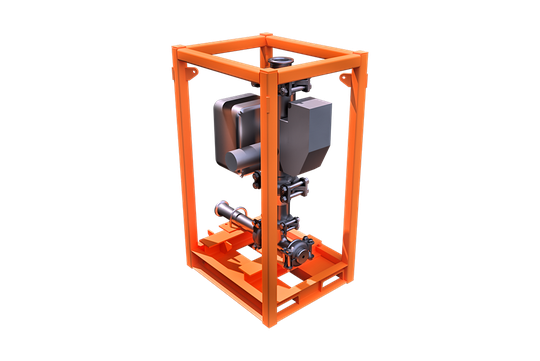

5K Strainer Unit

The FourPhase Strainer unit is intended for use in offshore topside applications where solids can be present at surface during flowback operations. It is typically used to separate solid particles >8 000 micron but the insert mesh is adjustable depending on application and expected solids.

Technical Specification Strainer Unit

Control Container

A 20 ft partitioned container. One partition is a workshop with all applicable tools and spare parts. The other is a control room where any equipment supplied by FourPhase can be remotely operated.

Technical Specification Control Container

Degassing Vessel

Designed to remove virtually all entrained gases, including hydrogen sulphide and corrosive oxygen from return fluid. It separates gas, hydrocarbon liquid, and water by reducing the velocity of the fluid flow.

Technical Specification Degassing Vessel

Storage Vessel

Part of our flowback package system for efficient solids handling. The low pressure, 50bbl storage tank stores produced liquids before disposal. Capable of holding a complete coiled tubing volume to provide a storage option should any issues occur in the process plant.

Technical Specification Storage Vessel

Duplex Production Pipework

To ensure seamless rig-ups, all applicable clamps, seals and tools required for installation are delivered in a complete solution managed by our team.