Automated and remote operations - A core strategy

As the industry moves towards autonomous platforms we have invested heavily in our technology to ensure safe, automated solids management is being delivered today. As a result, when and where the IT infrastructure allows, our systems can be remotely monitored and operated.

Remote operations:

Our definition and capabilities

Remote monitoring (one-way communication)

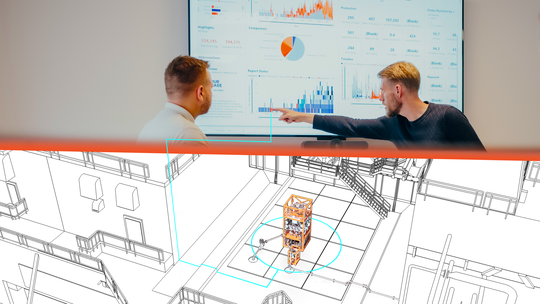

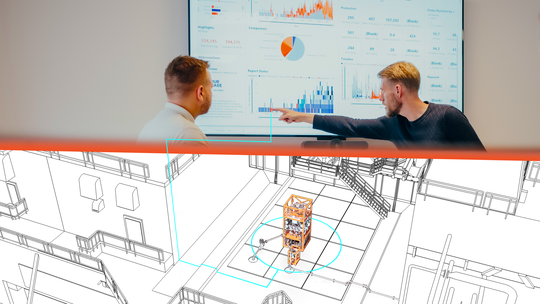

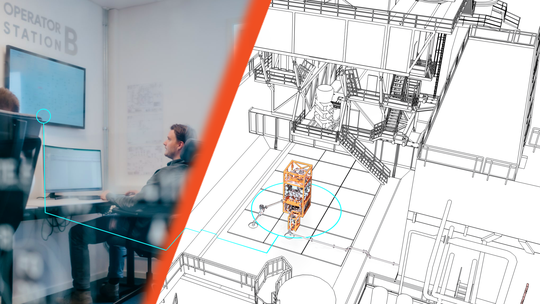

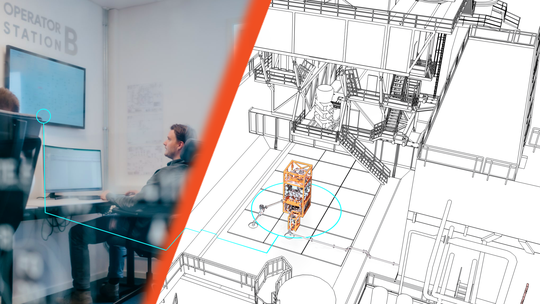

FourPhase can currently receive data from the solids management system remotely and create a replica display from our HQ in Bergen. Data can be relayed to specified locations and is accessible via our online dashboards from anywhere in the world.

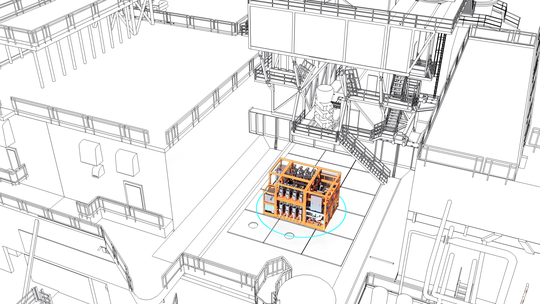

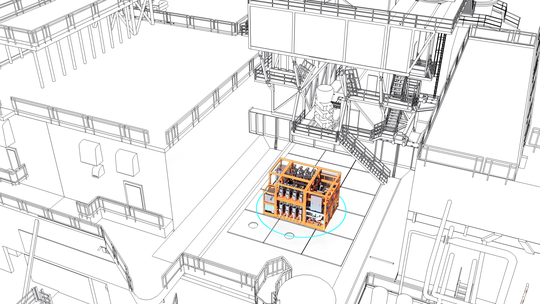

On-site Remote operation (two-way communication)

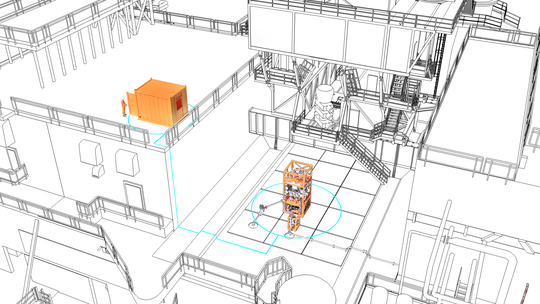

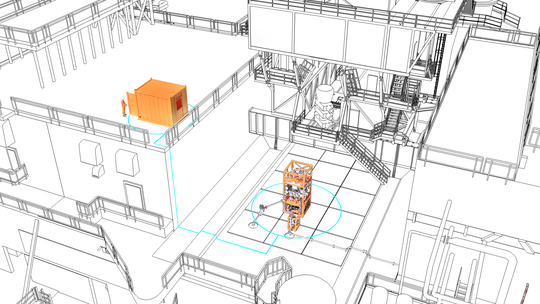

All FourPhase systems can be operated remotely on-site from an operator station/container, located in a safe and less intrusive area of the offshore site (i.e. outside the red zone).

Autonomous operation

FourPhase have delivered fully autonomous systems installed for unmanned installations. These systems do not require personnel other than for bagging solids and can operate independent of human interaction. This type of system is currently in operation in the South China Sea and has been since 2018.

Off-site remote operations (two-way communication)

Unassisted remote operations (with no personnel present at the asset), require the installation of additional sensory and mechanical redundancies (i.e. shut-off valves and relief systems). This can be developed on demand.

Replicating offshore

Our comprehensive Flow Loop is a full sized model of an offshore installation with EX certified valves, flow meters and a solids injection hopper to simulate sand events. With a camera link to the operations centre testing and offshore event simulations can be carried out to support project planning, training or remote operations.

See how our solids management expertise ensures project success

Operations and Technology Centre

Located in Bergen, our state of the art operations and test centre links to any remote operation in real time. From here we can remotely, or physically, gather experienced project managers to enhance knowledge transfer across projects, supporting the goal of zero downtime.

Reduce POB

Critical remote operation removes manual handling and people in exposed zones. The remote capabilities can lower POB, during ongoing production. Our systems are designed to eliminate risks, reduce cost and remove logistics associated with people offshore.

Contact us and learn how remote operations reduce risks and costs

Insights

Overall

Reduce POB and associated risks

Removes manual handling and people in exposed zones

Decrease costs, with the ability to manage more units remotely at a given time, synergies create economical gains

Have the experts in one room, enabling knowledge transfer and sharing

Removes manual handling and people in exposed zones

Decrease costs, with the ability to manage more units remotely at a given time, synergies create economical gains

Have the experts in one room, enabling knowledge transfer and sharing