A modular system for specific scenarios

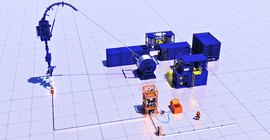

Our expertise in solids management and cleanout operations make us ideally suited to facilitate a variety of plug and abandonment (P&A) campaigns. Our modular closed loops units are small (2m x 2m) in footprint and designed to cater to specific operational scenarios.

Over the next 40 years, it is estimated that 3,000 wells on the Norwegian Continental Shelf will need to be plugged.

Coiled Tubing Clean-Out

Real-time decision making enables a proper cleanout, and provides operators with the data needed to assess the state of the well before plugging.

Furthermore, as an automated system, the risks commonly associated with manual handling are removed as no additional personnel are needed offshore.

Furthermore, as an automated system, the risks commonly associated with manual handling are removed as no additional personnel are needed offshore.

Learn how we optimize coiled tubing interventions

Designed to integrate

Our DualFlow unit is the smallest dual cyclonic desander on the market with its 2x2 metre footprint. This allows for easy integration on deck alongside a Coiled Tubing stack, creating a flexible system which only requires a single operator. Ideally suited for operations requiring small footprints, such as ship based interventions or brownfield applications where limited deck space poses a challenge.

Explore our compact and powerful desanding solutions

A safer approach

Our closed-loop system is testament to our commitment to safety and environmental stewardship. By containing all hydrocarbons and hydrogen sulphide gas (H2S) while separating solids, we ensure that P&A operations are not only efficient but also environmentally responsible.

Our versatile equipment ensures that P&A operations are not only compliant with regulations but also contribute to a sustainable future for the industry.

Our versatile equipment ensures that P&A operations are not only compliant with regulations but also contribute to a sustainable future for the industry.

See how we reduce emissions and improve efficiency

Insights

Overview

Driven by real-time solids data

Equipment is easy to integrate and highly adaptable

Ideally suited for operations requiring small footprints

Closed-loop system enables environmentally friendly operations

Equipment is easy to integrate and highly adaptable

Ideally suited for operations requiring small footprints

Closed-loop system enables environmentally friendly operations