Ensure continuous production without downtime

Installing a desander for online jetting can remove solids from the production separator during production. Solids are separated, and any fluids are sent back to the process for further refining, reducing the operational environmental footprint while maintaining production.

No more manual handling

With online desanding of the production separator, FourPhase removes the need for hazardous manual labour to remove the sand from separators, enabling better work environment offshore.

Hover image to play animation >>

Hover image to play animation >>

Avoid discharge into the sea

Jetting proppants to sea is typically not allowed on the NCS without a dispensation granted by the environmental authorities. Dispensations are, however, regularly granted on the NCS. This is a point of environmental concern, especially when there is an efficient and cost-beneficial way to collect the proppants and avoid direct discharge into the sea by jetting.

On the Norwegian Continental Shelf (NCS), jetting operations compromise on average 44 tons of oil emitted to the sea every year.

Designed for production

A 5K psi DualFlow de-sander has the capacity to handle both initial cleanout with large amounts of proppants as well as regular flowback with a mix of proppants and sand. No mechanical switchouts are required, along with the inevitable production stoppages. Instead, you have continuous production. Optimized for maximum production flow and solids removal, bringing a range of financial and environmental benefits.

Enhance production efficiency with DualFlow

Best of both worlds

We believe that operators can have the best of both worlds. Separating the proppants upstream – before the production separators - removes jetting emissions from separators, saves erosion issues downstream and enables optimal production flow during all well phases.

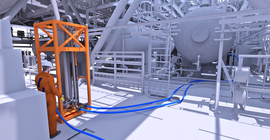

Deploying the DualFlow as a temporary jetting solution

Maintains production as our two-vessel design ensures the well is never offline

Allows for simple hook-up with a compact skid mounted design

Delivers closed loop operations removing manual handling of solids

Require no capital expenditure outlay all OPEX

Can tie-in to existing production separator inlet and outlet nozzles

Allows for simple hook-up with a compact skid mounted design

Delivers closed loop operations removing manual handling of solids

Require no capital expenditure outlay all OPEX

Can tie-in to existing production separator inlet and outlet nozzles

Insights

Overview

Separate solids sand during production

No manual handling and closed loop system

Remove emissions to sea related to jetting from separators

Environmental compliance

No manual handling and closed loop system

Remove emissions to sea related to jetting from separators

Environmental compliance