Core applications

70% of fields globally have a solids problem, where some kind of solids handling equipment is needed. Our systems work across upstream, midstream and downstream applications, enabling the efficient management of solids during the life of a well.

Solids producing wells

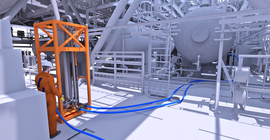

Eliminate choked back or shut-in wells: Our method ensures the continuous removal of solids upstream the separator, thereby increasing production rates and reservoir permeability.

Optimised production

Coiled tubing flowback

No downtime: Informed by real-time solids data, our technology enables better decision making and a more efficient Coiled Tubing clean-out.

Coiled tubing

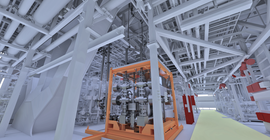

Online separator jetting

Optimised production during jetting operations of production separators. Our approach eliminates downtime and the HSE risks associated with manually emptying separators.

Online jetting

Produced water management

Our solids removal solution improves water quality and eliminates the cost of sand eroding re-injection pumps.

Produced water

Plug & abandonment

We eliminate the need for discharge to sea and enable environmentally responsible P&A operations

P&A

Case Studies

“We are very satisfied with FourPhase’s removal efficiency, which we estimated to 99%, as opposed to your competitor’s cyclone that we measured to between 85 - 95%.”

- Major Norwegian Operator, Engineer Well Operations

- Major Norwegian Operator, Engineer Well Operations

A clean approach

Our technology separates oil from solids – leaving clean sand and avoiding contaminated solids being discharged into the sea via jetting or enabling it to be transported as normal freight. Improving the oily water separation process also removes all of the sand from the water, resulting in a higher quality of produced water, which helps protect equipment against erosion.

Discover our sustainable solutions for oil and gas production

Beyond oil and gas

Our technology also has applications far beyond oil and gas – including water management, swarf and cutting management, mud conditioning and general processes. If there is a market need then we are committed to new product development. So, if you have a challenge you’d like us to consider, please get in touch.

Get in touch with our solids experts for more information

Overview

Solid management solutions for the life of a well

Production Flow Recovery methodology

Enable the management of solids in real time

Separates oil from solids – leaving clean sand

Our technology also has applications far beyond oil and gas

Production Flow Recovery methodology

Enable the management of solids in real time

Separates oil from solids – leaving clean sand

Our technology also has applications far beyond oil and gas