Production maintained - online desanding of separator

Norwegian North Sea, 2024

FP-1201

Challenge

A customer in the Norwegian North Sea had a production separator that required removal of solids. The expected solid size was between 20-800 µm. The customer expected the well to produce around 240 m³/day, which was in the lower region of the capacity requirement for the standard DualFlow cyclone inserts. Therefore, a new insert design had to be developed, tested, and manufactured before the planned operation.

Solution

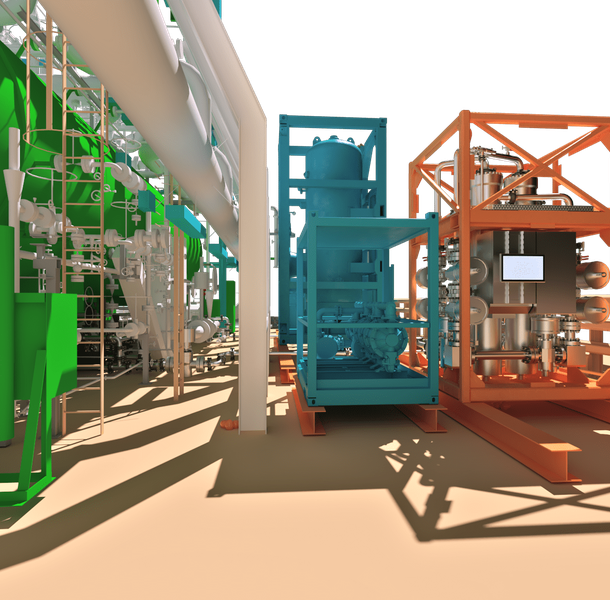

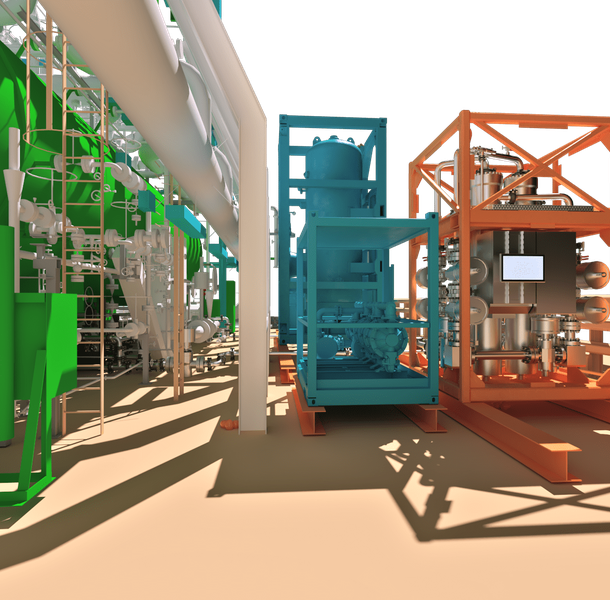

Based on FourPhase's extensive operational solids separation database, we defined parameters for successful separation efficiency. A new insert design was developed and manufactured in a concise time frame to test our hypothesis. The design was approved using the in-house test loop in Bergen, and the new inserts were manufactured and then installed in a DualFlow. The DualFlow was part of an Expro setup to enable online jetting of the production separator. ClampOn sand detectors were installed upstream and downstream of the DualFlow to measure efficiency.

Results

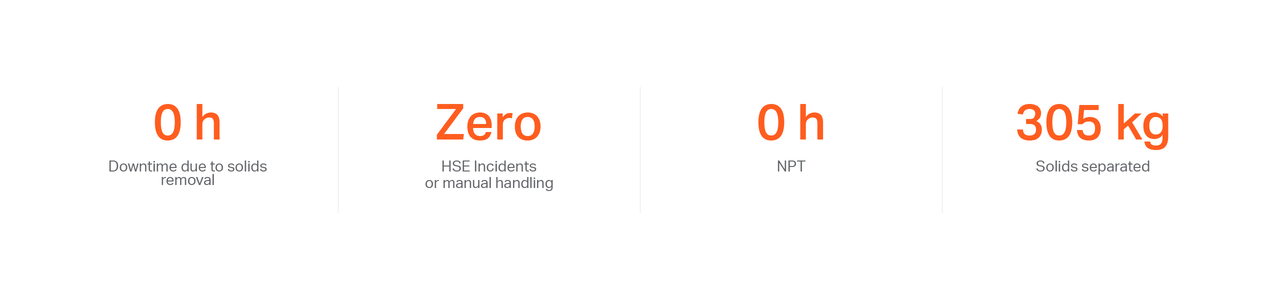

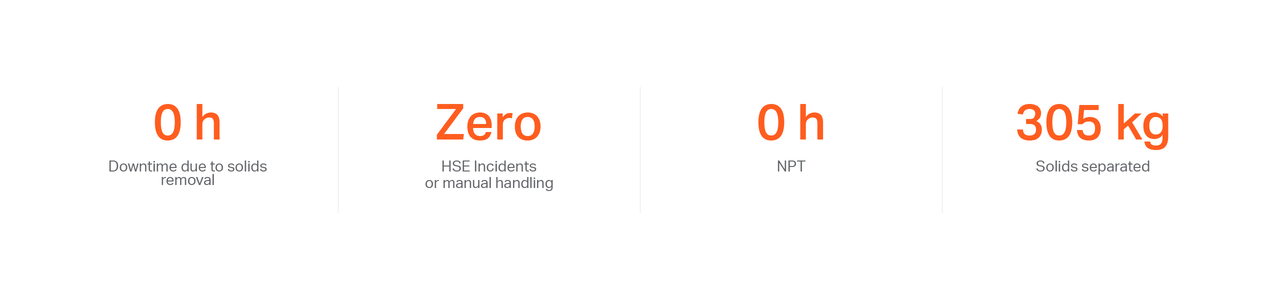

During seven days of operation, the DualFlow successfully separated 305kg of solids. No readings indicated solids on the sand detector downstream of the DualFlow, and the customer did not report solids carryover. This showed that the DualFlow's efficiency was as expected. Most importantly, by performing an online jetting operation, we successfully eliminated the need for manual handling to empty the separator, a significant relief for the customer.

Download case study pdf

Get in touch