Insights: How Solids Management as a Service positively impacts project economics

By utilising Solids Management as a Service, it is possible to unlock value for late life assets in situations where CAPEX intensive modification projects are seen as uneconomical. “As a service” models are not new to the energy sector, but they are new with regards to process equipment. The standard approach is the traditional ETO (Engineered to Order) executed through an EPC (Engineering, Procurement, Construction,) model mindset, typically used in process facilities.

Why a solids management strategy is needed

The main reasons to limit oil (and solids) production is often erosion, separator capacity and HSE. Reducing the production flow below the sand lift rate means less sand is produced topside, however, the build-up in the wellbore continues. It is possible to eliminate these challenges by implementing solids management downstream of the wellhead and upstream of the production separator.

Where several wells on a field are experiencing solids production, it is possible for a desander to be placed on multiple wells. This is because the desander, such as the DualFlow 5K, can route through several wells on a field, one at a time. The desander ensures the flow is as high as possible but below the erosive threshold (set by DNV-RP-O501) and eliminates sand from entering the process equipment topside.

Where several wells on a field are experiencing solids production, it is possible for a desander to be placed on multiple wells. This is because the desander, such as the DualFlow 5K, can route through several wells on a field, one at a time. The desander ensures the flow is as high as possible but below the erosive threshold (set by DNV-RP-O501) and eliminates sand from entering the process equipment topside.

The traditional EPC mindset to solids management

It is well known that evaluating, procuring, and installing process equipment can be a long and tedious process. In many cases, purchasing results in a modification project with high CAPEX investment, multidisciplinary teams, and substantial project management efforts just to enable implementation. From start to finish, the CAPEX approach could take around two years to complete before installation takes place.

Traditional CAPEX processes serve their purpose but do not offer the same level of flexibility and expertise that ‘as a service’ models do.

Typical challenges of EPC include:

• The purchase model requires intensive training and upskill of the end user, which takes time. This means that the commercial value to the business is not immediately unlocked.

• By placing solids management with the end user, the existing operations team must take on extra tasks. Already focused on the entire production facility, they are now additionally responsible for managing solids production.

• Solids cause erosion, and because of this, expert maintenance is required. Without a service agreement in place, end users are required to conduct this ongoing maintenance to ensure the equipment is kept operational.

• Reservoir characteristics change over time. Purchasing a desander limits the possibility of adapting and updating equipment to the changes in the reservoir pressure, flow etc.

• Total Cost of Ownership (TCO) of installing a new piece of equipment starts from the initial discussion. As the reservoir production profile changes and evolves over time, the first design of the equipment can become outdated quickly. This makes procuring a simple outcome-based service more efficient.

With alternative solutions available, there are significant upsides compared to the traditional modification project route.

Traditional CAPEX processes serve their purpose but do not offer the same level of flexibility and expertise that ‘as a service’ models do.

Typical challenges of EPC include:

• The purchase model requires intensive training and upskill of the end user, which takes time. This means that the commercial value to the business is not immediately unlocked.

• By placing solids management with the end user, the existing operations team must take on extra tasks. Already focused on the entire production facility, they are now additionally responsible for managing solids production.

• Solids cause erosion, and because of this, expert maintenance is required. Without a service agreement in place, end users are required to conduct this ongoing maintenance to ensure the equipment is kept operational.

• Reservoir characteristics change over time. Purchasing a desander limits the possibility of adapting and updating equipment to the changes in the reservoir pressure, flow etc.

• Total Cost of Ownership (TCO) of installing a new piece of equipment starts from the initial discussion. As the reservoir production profile changes and evolves over time, the first design of the equipment can become outdated quickly. This makes procuring a simple outcome-based service more efficient.

With alternative solutions available, there are significant upsides compared to the traditional modification project route.

Solids Management as a Service

With Solids Management as a Service model, solids management is provided as an instant ongoing service that can have an immediate impact on production economics. The service model is outcome-based and requires a minimum amount of project engineering, as the end user gets the results and solids experts manage the project.

The benefits of the rental approach:

• By deploying Solids Management as a Service, the desander can be installed quickly. This means the well does not need to be choked back and run at a sub-optimal rate. The result is that the well benefits from an unrestricted production flow.

• The well characteristics change over time, and cyclonic desanders need to be adapted continuously to the well to ensure optimal separation efficiency. With a purchase model, this is not possible, instead, the desander becomes less suitable as assets age and the production profile of the facilities falls outside the original design parameters for the cyclone. With Solids Management as a Service, the cyclone is continuously adapted as part of the service agreement to deliver high solids separation efficiency.

• With a business case created around increased production, there is an incentive for both service provider and customer to keep the wells at an optimal solids-free flow. Therefore, by ensuring optimal production with the use of a cyclonic desander for wells restricted to Acceptable Sand Rate (ASR), it is possible to increase production. In many instances, it can be increased by several hundred and, in some cases, even thousands of barrels per day for many operators.

• ESG benefits are also realised more quickly on a project. A desander, such as the DualFlow 5K, improves production to wells choked back to ASR. Other benefits include decreased emissions compared to coiled tubing, no jetting to sea and increased operator safety by reducing erosion (Link). By deploying the DualFlow 5K via a service model, these ESG benefits will immediately begin to impact a project.

The benefits of the rental approach:

• By deploying Solids Management as a Service, the desander can be installed quickly. This means the well does not need to be choked back and run at a sub-optimal rate. The result is that the well benefits from an unrestricted production flow.

• The well characteristics change over time, and cyclonic desanders need to be adapted continuously to the well to ensure optimal separation efficiency. With a purchase model, this is not possible, instead, the desander becomes less suitable as assets age and the production profile of the facilities falls outside the original design parameters for the cyclone. With Solids Management as a Service, the cyclone is continuously adapted as part of the service agreement to deliver high solids separation efficiency.

• With a business case created around increased production, there is an incentive for both service provider and customer to keep the wells at an optimal solids-free flow. Therefore, by ensuring optimal production with the use of a cyclonic desander for wells restricted to Acceptable Sand Rate (ASR), it is possible to increase production. In many instances, it can be increased by several hundred and, in some cases, even thousands of barrels per day for many operators.

• ESG benefits are also realised more quickly on a project. A desander, such as the DualFlow 5K, improves production to wells choked back to ASR. Other benefits include decreased emissions compared to coiled tubing, no jetting to sea and increased operator safety by reducing erosion (Link). By deploying the DualFlow 5K via a service model, these ESG benefits will immediately begin to impact a project.

Solids Management as a Service in action

With more than 10 years, one hundred individual projects and over 115 000 hours of operations with data collection from sand-producing reservoirs, working with a solids management expert, like FourPhase, means that expertise and data can be leveraged. There is a high level of data available and, by working with a solids expert, this data can be compared against previous learnings.

A key benefit of Solids Management as a Service means that the operators of the desander have worked on similar operations before. For example, the DualFlow 5K’s record for increasing production on solids producing wells is widely known. Here is a case study video for a well in the Gulf of Mexico which went from unmanageable and shut-in to well-managed and producing 6 000 bbl./day using efficient solids management solutions (link).

A key benefit of Solids Management as a Service means that the operators of the desander have worked on similar operations before. For example, the DualFlow 5K’s record for increasing production on solids producing wells is widely known. Here is a case study video for a well in the Gulf of Mexico which went from unmanageable and shut-in to well-managed and producing 6 000 bbl./day using efficient solids management solutions (link).

How it works in a typical scenario:

1. (Week 1) The operator identifies the well that is producing solids

2. An initial enquiry is sent identifying the issues

3. Feasibility study is conducted. This outlines parameters and data (well flow, flow composition and pressure). The separation efficiency calculations are carried out, and an appropriately sized system is specified

4. Project green light is provided, if achievable

5. (Week 2) 2–4-week mobilization period

6. (Week 6) Installation takes place, with 2-4 experts sent to the site to rig up

7. (Week 7) Effective solids management - Results are already seen by the operator

2. An initial enquiry is sent identifying the issues

3. Feasibility study is conducted. This outlines parameters and data (well flow, flow composition and pressure). The separation efficiency calculations are carried out, and an appropriately sized system is specified

4. Project green light is provided, if achievable

5. (Week 2) 2–4-week mobilization period

6. (Week 6) Installation takes place, with 2-4 experts sent to the site to rig up

7. (Week 7) Effective solids management - Results are already seen by the operator

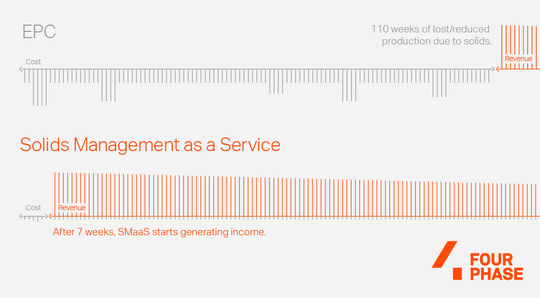

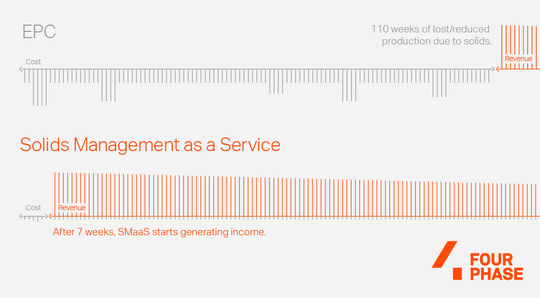

In comparison, EPC typically takes two years. In an ideal scenario, the timeline is 110 weeks. For Sand Management as a Service, the ideal case creates value for end users from week seven onwards. Whereas an EPC generates costs for the first 110 weeks.

The above service model shows the benefits for all assets; however, it is important to note that this is especially true for late-life assets. This is because they suffer more heavily from solids production, and there is less desire to invest heavily in them.

The above service model shows the benefits for all assets; however, it is important to note that this is especially true for late-life assets. This is because they suffer more heavily from solids production, and there is less desire to invest heavily in them.