Ensuring production by removing solids upstream produced water pump

Norwegian North Sea, 2023

Challenge

A customer in the Norwegian North Sea experienced continuous failure on their reinjection pumps. The failures caused shutdowns to the whole field, resulting in the loss of valuable production.

Solids not settling in the production separator caused them to follow the water line, eroding the produced water pumps.

With limited POB, an unmanned and remotely monitored solution was necessary. An automated solution would minimize exposure to risk for offshore operators and avoid unnecessary manual labour entering the separator.

Solids not settling in the production separator caused them to follow the water line, eroding the produced water pumps.

With limited POB, an unmanned and remotely monitored solution was necessary. An automated solution would minimize exposure to risk for offshore operators and avoid unnecessary manual labour entering the separator.

Solution

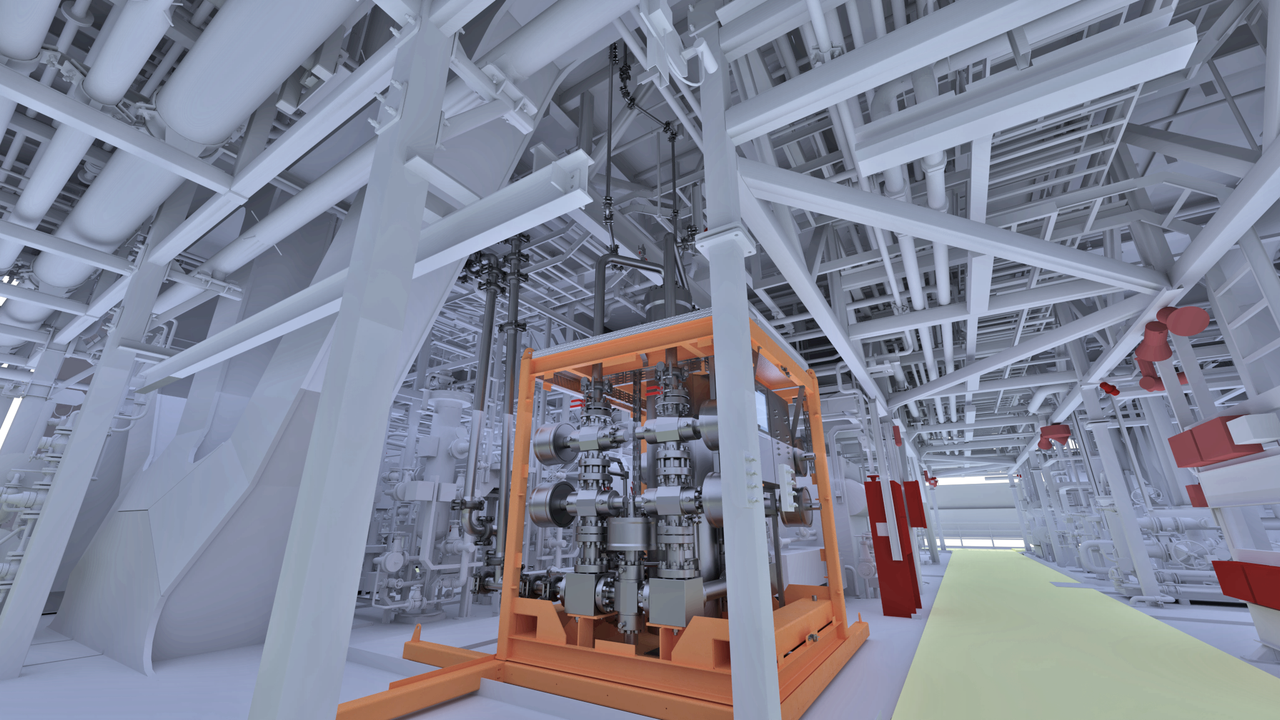

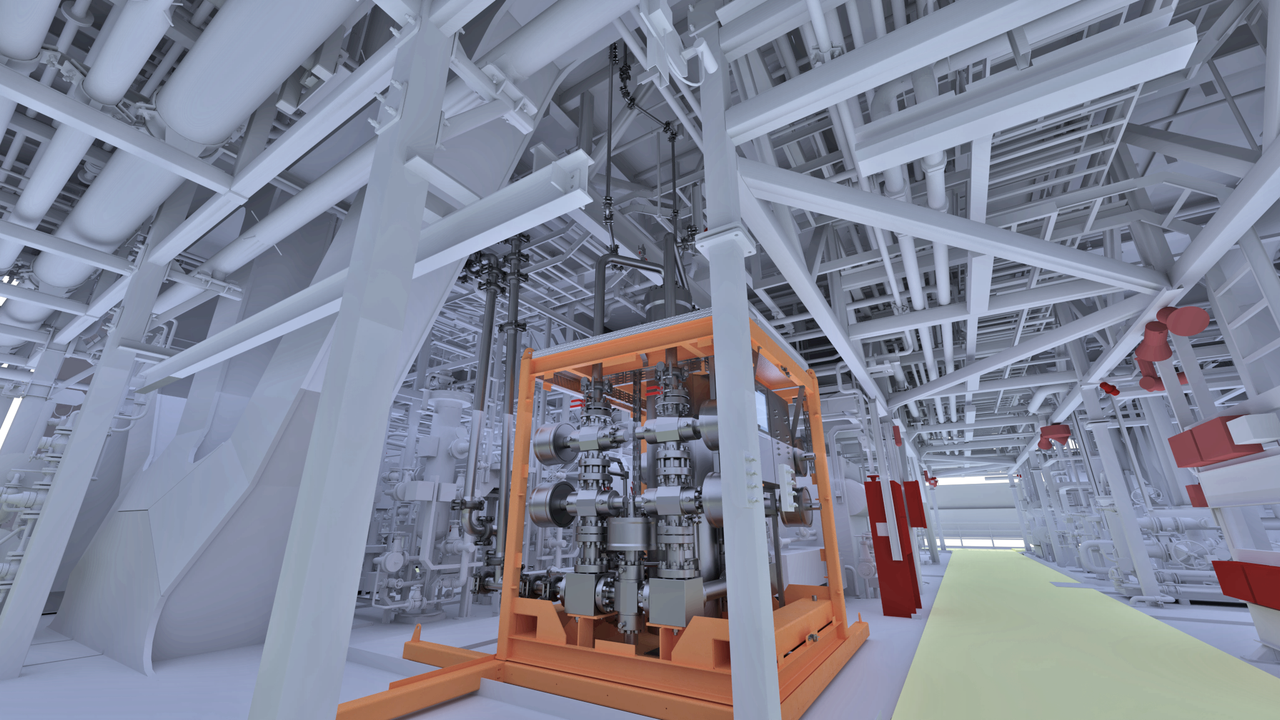

A DualFlow desander is installed downstream the separator and upstream of the reinjection pumps.

A combination of remote and unmanned operation ensured minimal POB was required on site. Real-time measurement of solids production enabled correlation with hydrocarbon production, unlocking valuable information to improve flow.

The DualFlow desander allowed for unconventional jetting of the separator by activating the jetting nozzles, closing the jetting outlet and allowing the solids to follow with the water outlet from the separator to the cyclonic desander.

A combination of remote and unmanned operation ensured minimal POB was required on site. Real-time measurement of solids production enabled correlation with hydrocarbon production, unlocking valuable information to improve flow.

The DualFlow desander allowed for unconventional jetting of the separator by activating the jetting nozzles, closing the jetting outlet and allowing the solids to follow with the water outlet from the separator to the cyclonic desander.

Result

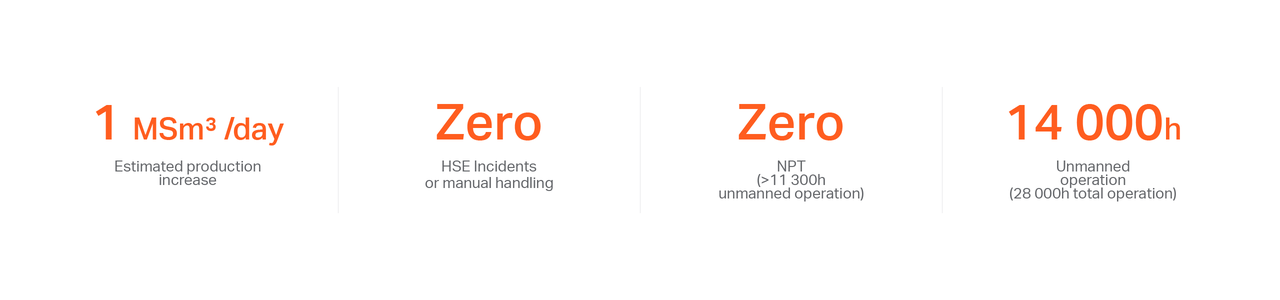

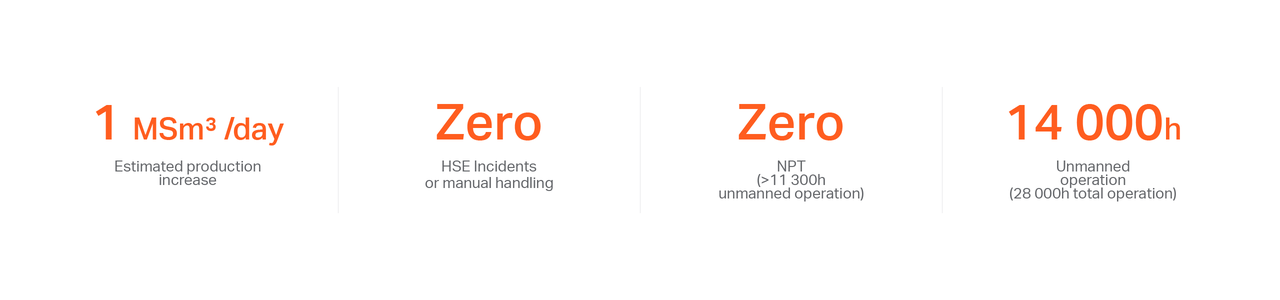

The field achieved an additional 1Msm3/day of continuous flow without downtime or loss of income due to solids in the reinjection pumps and minimal need for personnel offshore.

Zero HSE incidents during the entire operation. No confined space entry into the separator and maintaining separation

efficiency as sand is continuously removed, (20t to date).

With real-time measuring of solids, the customer better understands solids production from wells, enabling more accurate calibration of their sand sensors, further optimizing production and improving their understanding of production (choke opening, erosion wear and overall integrity).

Download case study pdf

Zero HSE incidents during the entire operation. No confined space entry into the separator and maintaining separation

efficiency as sand is continuously removed, (20t to date).

With real-time measuring of solids, the customer better understands solids production from wells, enabling more accurate calibration of their sand sensors, further optimizing production and improving their understanding of production (choke opening, erosion wear and overall integrity).

Download case study pdf

Get in touch