Efficient surface sand removal adds $2.6M monthly production

North Sea, 2023

Challenge

Achieve continuous flow from the well by managing sand production via inline de-sanding.

The well has not flowed for two years due to sand production being above the acceptable level for the platform facilities. The flowback operation is planned as a longterm production restoration, but the continuation of the operation is dependant on economic viability, namely $/BOE price. Minimum downtime for maintenance is an essential performance requirement. Remote monitoring and operation capability will be considered if production is extended into the medium to long term.

The well has not flowed for two years due to sand production being above the acceptable level for the platform facilities. The flowback operation is planned as a longterm production restoration, but the continuation of the operation is dependant on economic viability, namely $/BOE price. Minimum downtime for maintenance is an essential performance requirement. Remote monitoring and operation capability will be considered if production is extended into the medium to long term.

Solution

“FourPhase enabled production from the shut-in well, resulting in the highest-ever output on the field.”

Installing a FourPhase closed-loop sand management system consisting of a DualFlow, 2x SSV and 2x solids tanks. The system ensured improved HSE as manual handling was not required for emptying the separator nor to flush the DualFlow system, as this was managed automatically. To keep POB at a minimum, a remote monitoring solution was proposed for when the operation has stabilised.

Installing a FourPhase closed-loop sand management system consisting of a DualFlow, 2x SSV and 2x solids tanks. The system ensured improved HSE as manual handling was not required for emptying the separator nor to flush the DualFlow system, as this was managed automatically. To keep POB at a minimum, a remote monitoring solution was proposed for when the operation has stabilised.

Result

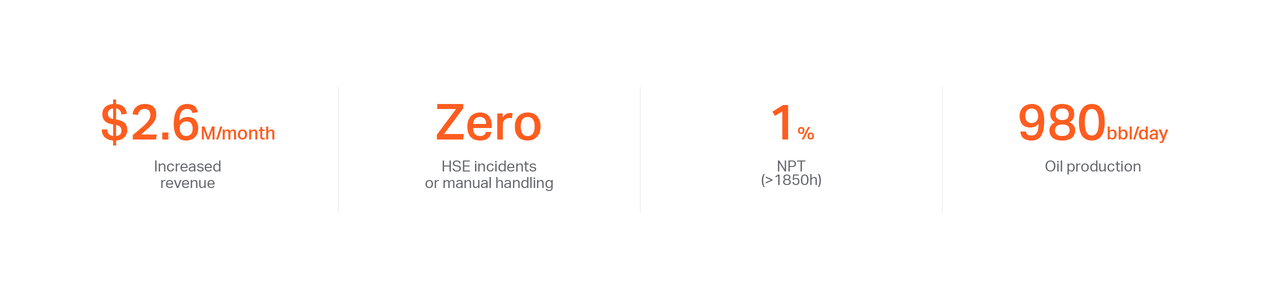

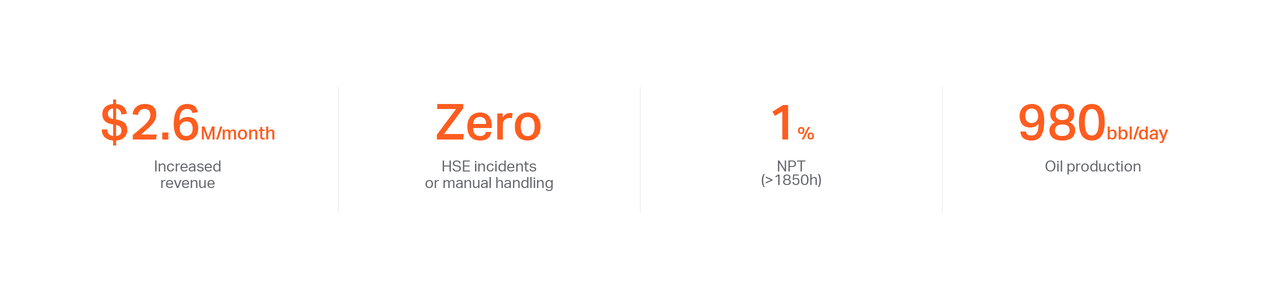

Continuous production worth $2.6M/month was maintained using a DualFlow desander. The well typically produced 1 000 bbl of oil and 1.8 mmscfd of gas per day.

No HSE incidents during the entire operation. No separator confined space entry and no manual handling because automated closed-loop flushing sequences ensured safe removal of solids. Remote off shore operation was conducted from a platform office, ensuring a safe work environment away from exposed work areas.

Download case study pdf

No HSE incidents during the entire operation. No separator confined space entry and no manual handling because automated closed-loop flushing sequences ensured safe removal of solids. Remote off shore operation was conducted from a platform office, ensuring a safe work environment away from exposed work areas.

Download case study pdf