Efficient surface sand removal adds $2.0M monthly production

North Sea, 2023

Challenge

Low production due to choked back well and more than 30% downtime. The goal was to achieve continuous flow by managing solids/sand production via wellhead desanding.

The well had limited uptime due to high solids production and lack of access to the test separator. In combination with low flow (below the solids lift rate), the risk of plugging the well completely was substantial, which would cause the well to be shut-in.

With minimal space available, the operator needed a compact solution to enable stable production of the well.

The well had limited uptime due to high solids production and lack of access to the test separator. In combination with low flow (below the solids lift rate), the risk of plugging the well completely was substantial, which would cause the well to be shut-in.

With minimal space available, the operator needed a compact solution to enable stable production of the well.

Solution

Installing a FourPhase solids management system (2x2m footprint), including a DualFlow desander and a choke manifold downstream of the wellhead. In addition, a bypass line was installed to maintain production independent of maintenance

requirements.

Through continuous operation and solids separation, the system ensured continuous hydrocarbon production with no solids entering the production separator. This was confirmed by the sand detection sensors downstream of the desander. With live data streams reported daily, production engineers could make fact-based decisions to optimise production.

requirements.

Through continuous operation and solids separation, the system ensured continuous hydrocarbon production with no solids entering the production separator. This was confirmed by the sand detection sensors downstream of the desander. With live data streams reported daily, production engineers could make fact-based decisions to optimise production.

Result

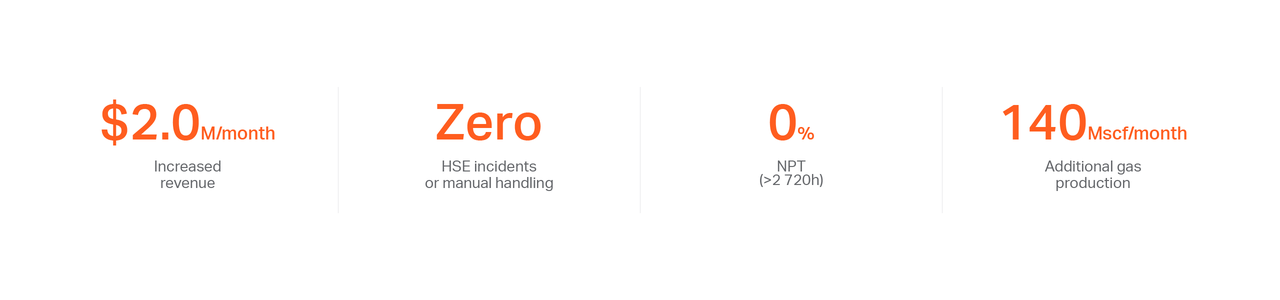

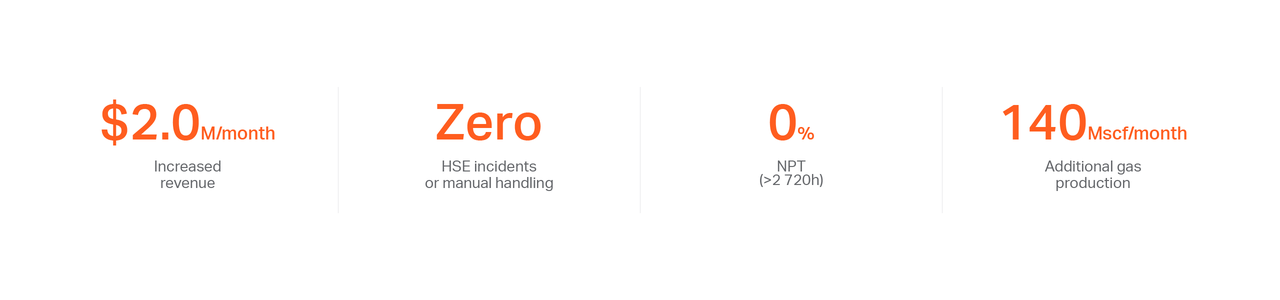

Continuous production worth $2.0M/month was enabled using a DualFlow desander. The well produced 140Mscf/month of gas.

With limited availability on the test separator, the well was previously repeatedly shut-in to control sand production. With the FourPhase desander installed, off shore hydrocarbon production was maintained, continuously generating revenue.

No HSE incidents and low NPT during the entire mobilisation/operation. Automated flushing sequences ensured safe removal of solids.

Download case study pdf

With limited availability on the test separator, the well was previously repeatedly shut-in to control sand production. With the FourPhase desander installed, off shore hydrocarbon production was maintained, continuously generating revenue.

No HSE incidents and low NPT during the entire mobilisation/operation. Automated flushing sequences ensured safe removal of solids.

Download case study pdf