$25M production maintained - online desanding of production separator

UK North Sea, 2020

UK North Sea, 2020

Challenge

Re-establishing three-phase separation on HP separator during oil and gas production. Estimated 60 tonnes of solids accumulated inside the HP Separator by way of a thermographic survey carried out prior to operations, causing potential erosion of control valves downstream.

The HP Separator internal jetting system for cleaning solids had never been used ahead of this operation, and the performance, efficiency, and expected solids rates of the internal jetting system were somewhat unknown. The water leg of a production separator in the North Sea was blocked.

The HP Separator internal jetting system for cleaning solids had never been used ahead of this operation, and the performance, efficiency, and expected solids rates of the internal jetting system were somewhat unknown. The water leg of a production separator in the North Sea was blocked.

Solution

Online desanding using DualFlow without shut down of production. Using the DualFlow desander, the water leg was brought back

to production, saving significant time and cost for the client compared to a complete production shutdown. Utilised internal jetting system to fluidise the sand – no manual handling for emptying separator. In addition to the DualFlow, an SSV and two closed loop-debris tanks were supplied.

to production, saving significant time and cost for the client compared to a complete production shutdown. Utilised internal jetting system to fluidise the sand – no manual handling for emptying separator. In addition to the DualFlow, an SSV and two closed loop-debris tanks were supplied.

Result

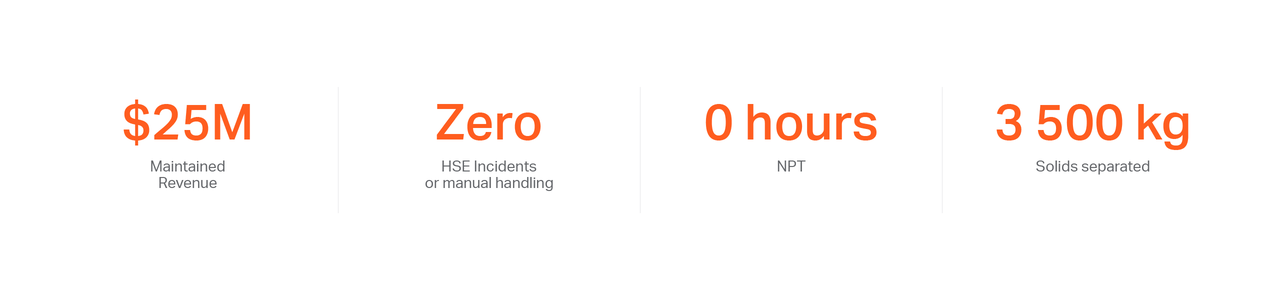

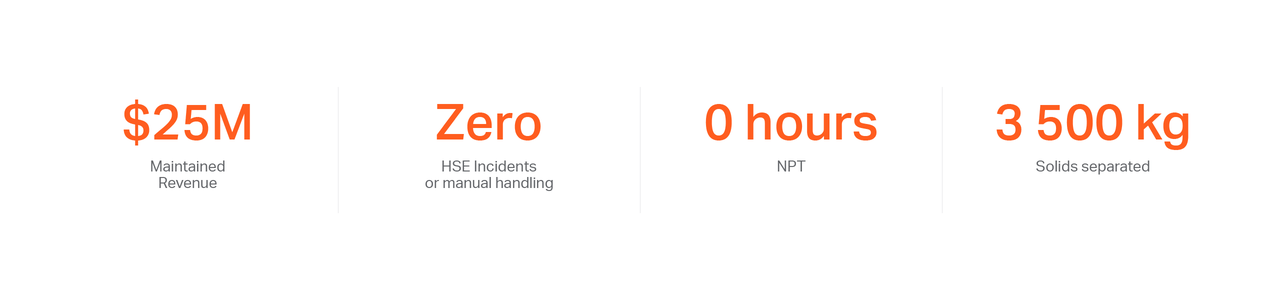

Continuous production worth $25M* was maintained using a DualFlow desander.

No HSE incidents or NPT during the entire mobilisation/operation/demobilization. No confined space entry and no manual

handling as automated fl ushing sequences ensured safe removal of 3.5 tonnes of solids.

* - $24.96M = $32/bbl x 39 days x 20 000 bpd

Download case study pdf

No HSE incidents or NPT during the entire mobilisation/operation/demobilization. No confined space entry and no manual

handling as automated fl ushing sequences ensured safe removal of 3.5 tonnes of solids.

* - $24.96M = $32/bbl x 39 days x 20 000 bpd

Download case study pdf