$17M production maintained - Online separator jetting

North Sea, 2020

Challenge

Re-injection pumps required costly maintenance and production shut down due to solids production. The Operator had two wells producing solids from a neighbour platform. Needed to confirm what type of solids the wells were producing before re-injecting to the disposal well. The operation required to flow and diagnosis of both wells through a 39km subsea pipeline and through the waterleg of a production separator. A connection was possible through the water leg of “separator C”. Potential full separators would require manual handling in confined space to remove solids if no automated solution could be provided.

Solution

Online desanding using DualFlow without shut down of production and no manual handling required. A DualFlow desander was connected to the water leg of a production separator saving significant time and cost for the client compared to a complete shutdown of production. FourPhase supplied a DualFlow desander and triplex pump solution to boost pressure downstream and overcome backpressure from the disposal well. Analysis of the solids produced confirmed if the client process equipment could handle the type of solids.

Result

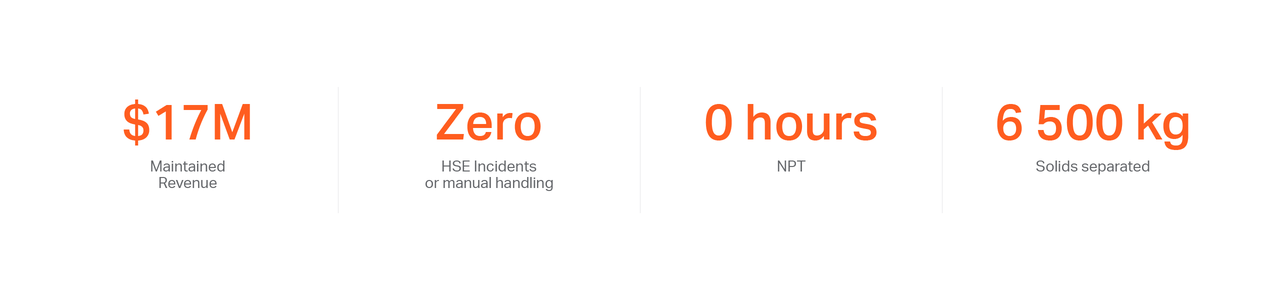

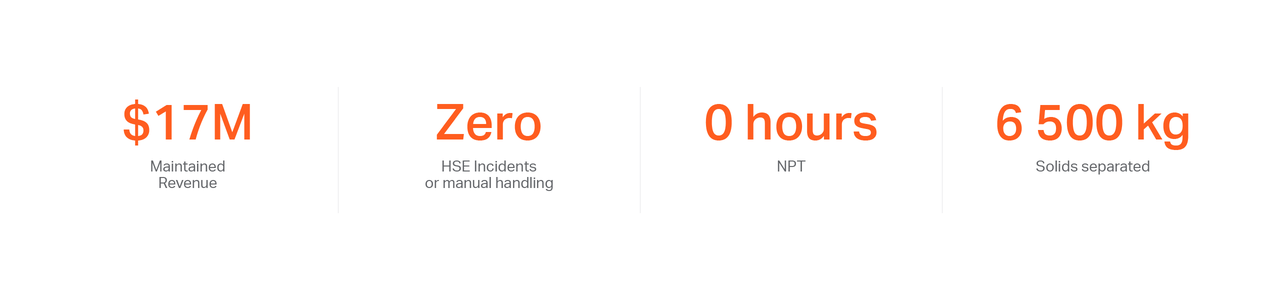

Maintained production worth $17M* with DualFlow as well as avoiding pump maintenance costs and extensive planning.

FourPhase enabled customers to confirm what type of solids production they had, enabling them to come up with a safe production rate (ASR). Dualflow was installed within a small 2x2m footprint on the available deck space on the platform. Pipelines were cleaned from solids and diagnosed using PIG, and 6.500kg of solids from pigging operation was effectively managed. Utilising a triplex pump overcame back pressure from a disposal well. FourPhase will return to produce wells upstream pipeline

* $16.8M = $60/bbl x 14 days x 20 000 bpd.

Download case study pdf

FourPhase enabled customers to confirm what type of solids production they had, enabling them to come up with a safe production rate (ASR). Dualflow was installed within a small 2x2m footprint on the available deck space on the platform. Pipelines were cleaned from solids and diagnosed using PIG, and 6.500kg of solids from pigging operation was effectively managed. Utilising a triplex pump overcame back pressure from a disposal well. FourPhase will return to produce wells upstream pipeline

* $16.8M = $60/bbl x 14 days x 20 000 bpd.

Download case study pdf