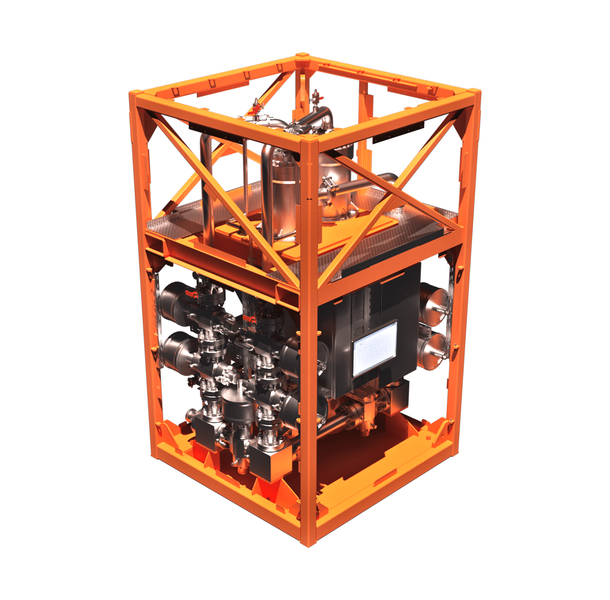

The most refined solids management technology in the world

The only dual cyclone desander on the market with a 2x2 meter footprint. With a fit-for-purpose, modular design, DualFlow strategically developed to create a flexible, stackable and compact solution that fits in easily on crowded platform environments.

Technical Specification 5K DualFlow Desander

Specification

US

SI

Dimensions

Height: 3 280mm

Width: 2 000mm

Depth: 2 000mm

Weight: 8 500kg

Width: 2 000mm

Depth: 2 000mm

Weight: 8 500kg

Materials

Pressure Vessel:

Duplex Duplex S31803

Valves: Duplex S31803 and AISI 316

/ AISI 316

Pipes: Duplex S31803 and AISI 410

Frame: Carbon steel (S355)

Duplex Duplex S31803

Valves: Duplex S31803 and AISI 316

/ AISI 316

Pipes: Duplex S31803 and AISI 410

Frame: Carbon steel (S355)

Certifications

DNV RP A203 - Qualified separation efficiency

NACE MR0175

PED 97/23/EC CE

Norsok Z-015, ZONE II

DNV 2.7-3 Portable Offshore Units

API 6A

ASME B16.34

NACE MR0175

PED 97/23/EC CE

Norsok Z-015, ZONE II

DNV 2.7-3 Portable Offshore Units

API 6A

ASME B16.34

Capacity*

Maximum flow rate (fluid):

3 168m³

Maximum flow rate (gas):

565 000 Sm³/day

Maximum sand rate:

200 kg/hrs

Particle size for 99.8% efficiency:

20 micron

* depends on the application

3 168m³

Maximum flow rate (gas):

565 000 Sm³/day

Maximum sand rate:

200 kg/hrs

Particle size for 99.8% efficiency:

20 micron

* depends on the application

Temperature

Min. operating temp:

-28 ºC

Max. operating temp:

+120 ºC

-28 ºC

Max. operating temp:

+120 ºC

Next generation cyclone technology

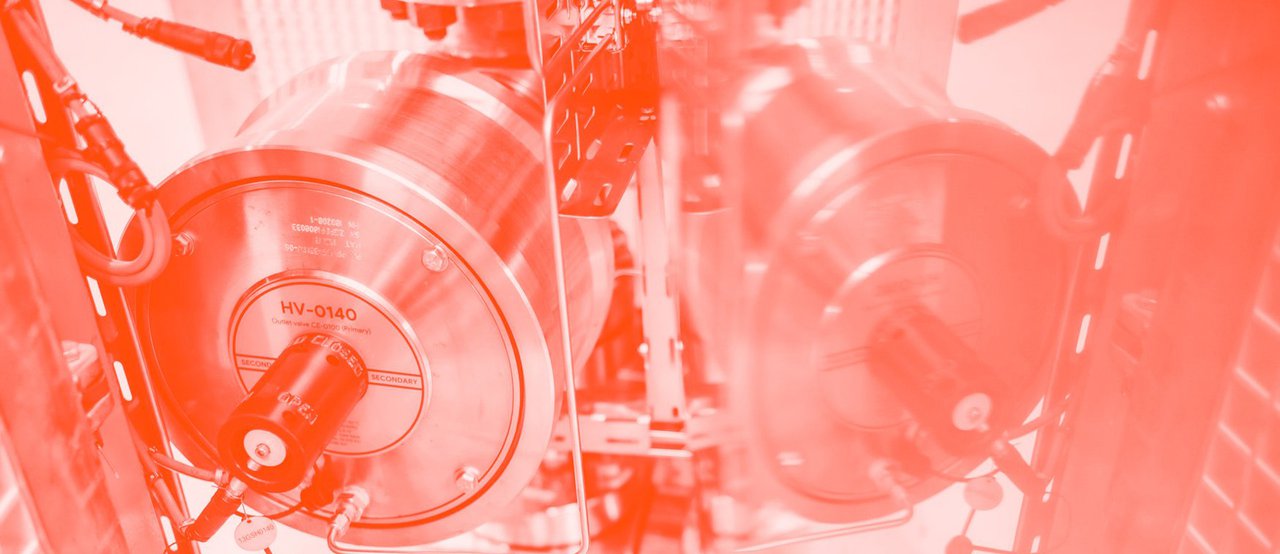

The DualFlow contains two patented, single liner cyclones in one unit. As one vessel is isolated and flushed, production continues through the other. 560 sensors return real time data on flow rate, pressure, temperature, weight, and asset integrity. Delivering a proven separation efficiency of 99.8%, and a dynamic range of 20 microns to 10mm solids up to 20 000 bbl/day and 20 MMscfd. The result is continuous production and better asset management, as the data allows early stages of erosion to be managed.

Working as a closed loop

FourPhase deliver hands-fee solids management to improve HSE offshore. By combining automated desanders and flushing with closed tanks, the system, any hazardous bi-products such as NORM, H2S or Benzene can be produced to the surface without exposure to offshore operators.

Maintain optimal flow rates

Proven to optimise production, DualFlow uses its real time data to tune well flow. By maintaining optimal flow rates, production is maintained at a consistent level, avoiding drops in production from choking back the well. This maximises solids free production, lowering the cost per barrel and enhancing production performance.

Learn how to maintain a higher flow rate safely

The first automated solids management system

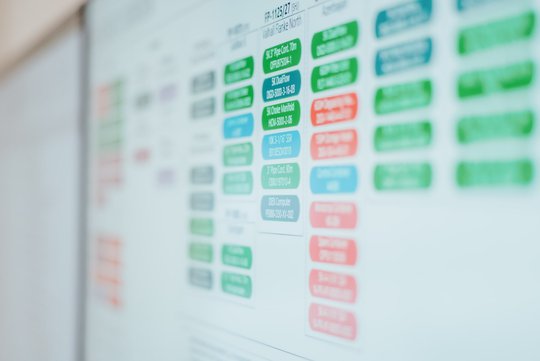

Capable of automated, remote operations, the system delivers solids-free production flow while reducing operational costs and eliminating risks related to human error. Connected to the system’s real time data, the DualFlow is aided by a control system which can perform advanced prediction simulations in real time.

See how real-time data transforms operations

Actively improves ESG reporting

With 560 sensors integrated into every DualFlow, the key is in the data that is captured in real time. This knowledge enhances decision making and reduces the need for carbon heavy interventions.

Enhance environmental performance with advanced technology

DualFlow improves the production of underperforming wells and enables operators to optimise asset integrity and increase field economics.

Discover our innovative solutions for optimized oil and gas production

Market differentiating technology

Compact 2m x 2m (6.6 ft) footprint

Separation efficiency of 99,8% and solid particle range from 20μm – 10mm

Highly automated system with remote operation

Real time solids measurement and data gathering

An interlock system to control all valves

Intuitive design with two vessels that can be run separately, in series and parallel

Single liner technology

560 inbuilt sensors

Separation efficiency of 99,8% and solid particle range from 20μm – 10mm

Highly automated system with remote operation

Real time solids measurement and data gathering

An interlock system to control all valves

Intuitive design with two vessels that can be run separately, in series and parallel

Single liner technology

560 inbuilt sensors

Benefits to your project

Fits easily on crowded platform environments

Enables retrofit without modification to offshore platforms

Reduces jetting of solids to sea

Reduces POB and mundane tasks on-site

Eliminates risk of operator error

Facilitates quick, confident decision making that cuts down associated risk

Reduces the need for carbon heavy interventions

Improves HSE

Enables continuous production

Facilitates a wide flow range

Ensures safe remote operations

Handles a variety of applications, including CT interventions, online desanding and production

Enables retrofit without modification to offshore platforms

Reduces jetting of solids to sea

Reduces POB and mundane tasks on-site

Eliminates risk of operator error

Facilitates quick, confident decision making that cuts down associated risk

Reduces the need for carbon heavy interventions

Improves HSE

Enables continuous production

Facilitates a wide flow range

Ensures safe remote operations

Handles a variety of applications, including CT interventions, online desanding and production